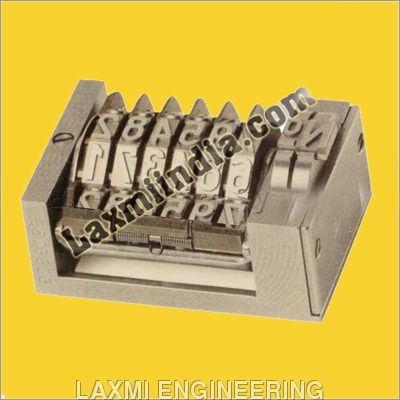

Drum Sequential Marking Meter Head

Drum Sequential Marking Meter Head Specification

- Drive Type

- Manual/Electric Drive

- Noise Level

- Low

- Surface Finish

- Smooth, Rust Resistant

- Features

- Precise Metering, User Friendly, Robust Construction, High Accuracy

- Lubricating System

- Grease Lubricated

- Motor Power

- 0.5 HP

- Size

- Standard

- Shape

- Rectangular Meter Head

- Usage & Applications

- Wire & Cable Marking, Drum Metering, Sequential Length Measurement

- Capacity

- Suitable for continuous operation

- Diameter

- Meter Roll Diameter: Up to 200 mm

- Product Type

- Drum Sequential Marking Meter Head

- Material

- Stainless Steel, Mild Steel

- Technology

- Sequential Marking, Mechanical Counter

- Power Source

- Electric

- Power

- 0.5 HP

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- Approx. 230 x 120 x 180 mm

- Color

- Grey, Silver

Drum Sequential Marking Meter Head Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Delivery Time

- 1 Days

- Packaging Details

- Packed in wooden boxes.

- Main Export Market(s)

- Middle East, North America, Eastern Europe, Australia, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Drum Sequential Marking Meter Head

From last many years, we are into the process of manufacturing and supplying a large collection of Drum Sequential Marking Meter Head. Our provided heads are precisely designed by making use of finest quality material. Superior in functionality, these heads are used to cater diverse printing requirements of electronic and electrical sectors. High in performance, the range of Drum Sequential Marking Meter Head is applicable for printing numerous specifications over the sheathed cables.

Features:

- Superb functionality

- East to use

- Rugged structure

Further Details:

the meter head of this machinery is of four numerical digits.

Advanced Sequential Marking Technology

Fitted with precise sequential marking technology and a mechanical counter, this meter head ensures each wire or cable is marked accurately according to set lengths. The robust construction is suitable for high-demand industrial environments and continuous operation, offering reliability with every use.

Durable Construction & Rust Resistance

Crafted from stainless steel and mild steel, and finished with powder coating, the device is designed to withstand harsh industrial conditions. Its rust-resistant surface and smooth finish not only enhance its longevity but also contribute to easy maintenance and a professional appearance.

Flexible and User-Friendly Operation

Offering both manual and electric drive, the Drum Sequential Marking Meter Head caters to various operational needs. Its grease-lubricated mechanism ensures low noise and smooth operation, while the compact rectangular design allows for simple integration into existing production lines.

FAQs of Drum Sequential Marking Meter Head:

Q: How does the Drum Sequential Marking Meter Head operate?

A: The meter head works by passing wire or cable through the device, where it utilizes sequential marking technology and a mechanical counter to measure and mark each segment accurately. The electric motor, rated at 0.5 HP, drives the mechanism, though manual operation is also possible.Q: What materials are used in the construction of this meter head?

A: The principal materials are stainless steel and mild steel, chosen for their strength and corrosion resistance. The device also features a powder-coated finish, making it durable and suitable for industrial applications.Q: When is it ideal to use this marking meter head?

A: This device is perfect for continuous or batch operations in wire and cable manufacturing plants, especially when precise sequential marking and reliable length measurement are required.Q: Where can the Drum Sequential Marking Meter Head be installed?

A: Its compact dimensions and standard size allow for easy integration into wire and cable production lines, drum metering setups, and length measurement stations across manufacturing facilities.Q: What is the process for lubricating this meter head?

A: The device features a grease-lubricated system. Regular lubrication as per the manufacturers guidelines ensures low noise, smooth functioning, and extended operational lifespan.Q: How does using this meter head benefit cable and wire manufacturers?

A: Manufacturers benefit from its high accuracy, robust build, low maintenance, and user-friendly operation. These features minimize errors and downtime, leading to improved productivity and cost savings in the long run.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Printing Machine Parts Category

Printing Letters Embossing Segment

Minimum Order Quantity : as per requirement Unit

Product Type : Other, Printing Letters Embossing Segment

Technology : Other, Embossing

Material : High Grade Brass

Color : Golden

Sequential Meter Marker

Price 15000 INR

Minimum Order Quantity : 01 Meter

Product Type : Machine Parts

Technology : Other

Material : STEEL

Send Inquiry

Send Inquiry